|

Water Cooling the GS-3A by KD5FZX Click on callsign for e-mail |

|

Manufacturing a GS-3A water cooling jacket

|

|

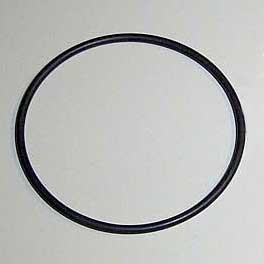

At left: the O-ring (2.75” O/D with 1/8” thickness). |

|

|

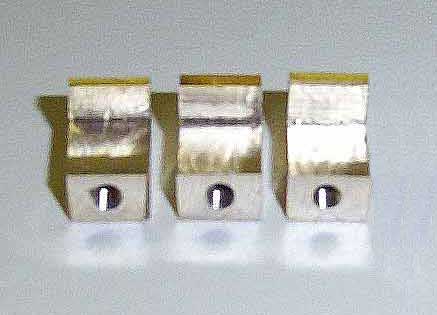

The clips are machined from brass stock. See drawing below. |

|

INSTRUCTIONS: |

|||

|

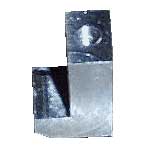

At left is the completed water jacket ready for installation.

|

|

|

|

|

Description & pictures of a water cooling system. |

go to the top

|

Best Viewed: MSIE 4.0 & higher, or Netscape 3.02 & higher, and screen set to 800x600 pixels This Page Last Updated: 17 May 2004 Feedback: Paul S. Goble, III, ND2X Copyright © 2003 -2004 by ND2X and KD5FZX, all rights reserved |